Accurate Metals specializes in custom Blanchard grinding services for various industries. Blanchard grinding is a cost-effective, highly precise method of removing substantial material from extensive surface areas. Our in-house Blanchard grinders allow us to handle low to high-volume production of parts up to 84 in. corner-to-corner and up to 10,000 lbs. in weight.

Custom Blanchard Grinding Services

- Process

-

Blanchard Grinding

- Automation Capabilities

-

CNC Controlled

- Material - Metals

-

Steel

Stainless Steel

Low Alloy SteelAlloy Steel

Castings

Others

- Part Length

-

Up to 84″ corner to corner

- Part Width

-

Up to 84″ corner to corner

- Part Weight

-

Up to 10,000 lbs.

- Flat / Parallel

-

± .005″, Tighter Tolerances obtainable

- Perpendicularity / Squareness

-

± .005″, Tighter Tolerances obtainable

- Tolerance

-

± .005″, Tighter Tolerances obtainable

- Surface Finish

-

Up to 63

125 (Standard)

- Lifting Capacity

-

5 ton

- Additional Services

-

Clean

Package

Bar Coding

*Free Delivery (150 mile Radius of Milwaukee or Rockford)

- Production Volume

-

Low to High Volume

- Lead time

-

Inquire for current lead times

Additional Information

- Industry Focus

-

Agriculture, Automation / Production Equipment,

Construction, Mining, Nuclear, Material Handling,

Municipal/ Government, Power Generation, Rail, Wind

- Intended Application

-

Components

Armor PlatingHeavy Duty Vehicle

OEM Components

- Industry Standards

-

ASTM

ANSI

ASME

- File Formats

-

AutoCAD (DWG, DXF)

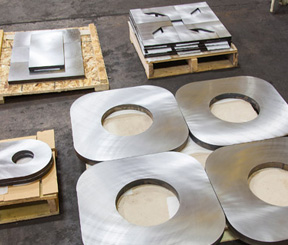

Examples of Our Work

- Flame Cutting of a Steel Crankshaft Counterweight for the Energy Industry

- Fabrication of a Steel Drive Ring for the Manufacturing Industry

- Fabrication of a Large Bearing Cap for the Mining Industry

- Flame Cutting of a Steel Rotor for the Electrical Industry

Custom Blanchard & Surface Grinding Capabilities

AMP offers highly precise Blanchard grinding services tailored to diverse applications. We cater to industries ranging from mining to nuclear power and produce customized products such as OEM components, heavy-duty vehicle parts, armor plating, and more.

Our experienced team works to tolerances of ±.005 in., for flat or parallel measurements, perpendicularity, or other dimensions, with the possibility of achieving even tighter tolerances. We provide surface finishes of up to 63 or a standard finish of 125 RMS.

Our Blanchard grinding process employs CNC-controlled automation, accommodating a range of metals, including:

- Steel

- Stainless steel

- Low alloy steel

- Alloy steel

- Castings

- Other metals

Our services also include cleaning, packaging, barcoding, and free delivery within a 150-mile radius of our Milwaukee or Rockford facilities.

Understanding Blanchard Grinding

First developed by the Blanchard Machine Company of Cambridge, MA, in the early 20th century, Blanchard grinding, also known as rotary surface grinding, is a globally acknowledged method for finishing flat surfaces. It employs a cylindrical grinding wheel and vertical grinding spindle for precise and accurate material removal.

While Blanchard grinding is ideal for large surface areas and high-volume projects, precision grinding techniques are better suited for smaller objects and more complex surface requirements. Regardless, all precision grinding techniques aim to create ultra-smooth surfaces without leaving patterns or bumps.

Get in Touch for Your Blanchard Grinding Needs

For projects demanding precise removal of material from large surface areas, Blanchard grinding offers a cost-effective solution. AMP provides expertly crafted components with quick turnaround times and delivers free of charge within 150 miles of either our Rockland, Illinois, or Milwaukee, Wisconsin locations.

With over 25 years of delivering high-quality custom metal fabrication services to the Midwest, we are ready to meet your project’s unique needs. Contact us or request a quote to get started.