Accurate Metal Products has been in the steel sheet and plate manufacturing industry for almost 30 years, allowing us to learn traditional and modern processes for achieving quality sheet and plate products. Currently, our team is keeping up with the trends to utilize the most efficient methods while delivering high-quality results. With our expertise in manufacturing, you can expect accurate outcomes that meet your specifications.

We take pride in our state-of-the-art manufacturing facility, equipped with advanced machines and tools to ensure consistent and precise production. Our skilled workforce is highly trained and experienced, using their knowledge to produce steel sheet and plate products that meet the highest standards of quality, regardless of your project’s complexity. With our help, you can expect exceptional parts and components that not only meet but exceed your expectations.

Main Capabilities and Services

We’re constantly evolving and adapting to new processes and techniques to stay ahead in the competitive steel sheet and plate manufacturing industry. Fortunately, we have found a unique blend of manufacturing procedures that allow us to offer concise and superior products while maintaining our commitment to quality. Our main capabilities and services include:

SERVICES

Oxy-Fuel

Flame Cutting

Specializing in oxy-fuel precision flame cutting, oxygen and fuel gas facilitate the thermal cutting process to cut through steel materials easily. Cutting through thicker materials with straight and accurate edges is possible and can be done in a shorter amount of time through precision flame cutting without sacrificing quality.

Oxy-Fuel

Flame Cutting

SERVICES

Precision Plasma

Cutting

A jet of plasma and compressed gas is employed to cut through steel materials with outstanding precision. Since high-speed plasma is utilized in the process, it also results in high cutting speed.

Precision Plasma

Cutting

SERVICES

Precision Laser

Cutting

A high-power and incredibly focused laser beam is produced to cut through steel metals and plates. Remarkable accuracy and smoother edges are expected since it melts or burns the material.

Precision Laser

Cutting

SERVICES

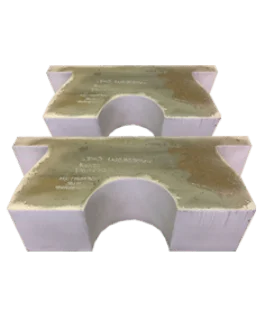

Blanchard

Grinding

Simply put, Blanchard grinding is also known as rotary surface grinding. It’s ideally used in workpieces or products with a larger surface area while ensuring part-to-part thickness consistency.

Blanchard

Grinding

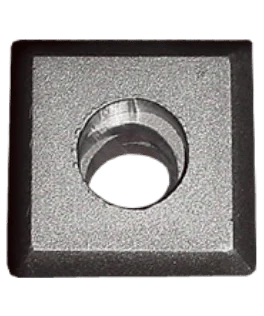

SERVICES

Abrasive

Blasting

Using pressurized air or water to propel abrasive media, abrasive blasting can easily smoothen/roughen a surface, shape it, or remove surface impurities (coating, corrosion, and rust) from steel products.

Abrasive

Blasting

SERVICES

Steel

Processing

Expect more durable products while adding value to your business, as we facilitate steel processing services while producing consistent outcomes. Whether you need drilling, sawing, or heat-treating services for your steel products, we’ve got you covered.

Steel

Processing

About Us

What to Expect from Us

Our experience and knowledge in steel metal manufacturing earned us the title of one of the industry’s most reliable and trustworthy companies. We aim to produce products that will guarantee the success of your projects for more years to come. Our team is dedicated to giving top-notch customer service, ensuring that your needs and specifications are met with the utmost attention and care.

Exceptional Steel Fabrication Services

Since 1995, we have evolved and expanded our operations to manufacture steel products that will improve our client’s bottom line. It shows how we’ve committed to providing exceptional custom steel fabrication services for over 20 years. Nothing and nobody can compare to the level of expertise and efficiency that our team can offer.

Remarkable Customer Service

Our customer service is proactive and responsive, as we’re able to accommodate your special requests and ensure you receive your steel products on time. Our goal is to establish a long-term partnership with our clients based on trust, reliability, and exceptional service.

Industries Served

Numerous demanding industries utilize steel sheet and plate parts and components for varying applications. Due to its substantial uses, we have become acquainted with the specifications and requirements of each sector, which is how we became their trusted supplier.

- Agriculture: Sheet metals are employed in the agriculture sectors for the construction of farming equipment and machinery, including tractors, harvesters, and plows. Structures, such as barns and silos, also utilize steel due to its durability and ability to withstand the rigors of farming operations.

- Construction: From structural components to decorative elements, steel sheet products are widely used in the construction industry for their versatility and strength. They are employed in the construction of buildings, bridges, and more.

- Defense: Steel plates are popular in the defense sector, as they’re utilized chiefly to produce defense equipment and vehicles, such as armor, tanks, and a plethora of military equipment. It’s also used to build fortifications to support their critical military operations.

- Energy: For oil and gas equipment fabrication, steel is one of the most used materials due to its high strength and corrosion resistance properties. It’s also utilized in building wind turbines, power transmission towers, and other energy-related infrastructure.

- Manufacturing: From heavy machinery to simple hand-held tools, steel sheets and plates play a crucial role in producing these essential devices for the manufacturing industry.

- Mining: Off-road and underground vehicles and equipment, as well as structures such as mine shafts and processing plants, require the resilience of steel products to withstand harsh mining conditions.

- Municipal/Government: The public sector relies on steel products for infrastructure development, transportation systems, and other essential facilities.

- Transportation: Steel is the go-to material in the transportation industry not only for its robust properties but also due to its lightweight characteristics.

Ready to Take Your Projects to the Next Level?

Steel is an important element in almost all industries due to its wide range of uses and applications. They’re easy to work with, malleable, can withstand tremendous pressure, and are highly durable. As a leading steel sheets and plates manufacturer, we understand the importance of delivering top-quality products and services to our clients.

From precision flame cutting to steel processing, we have the dedication to provide unprecedented results, you can count on us to take your projects to the next level. Don’t settle for anything less than perfection – choose us as your trusted partner in steel manufacturing. Check out our project gallery for more examples!

If you want to learn more about our services and capabilities, feel free to contact us today! You may also speak to one of our experts, and we’ll be more than happy to answer your questions and provide you with a custom quote. Let us help you achieve success in your projects today!